Über uns: Das macht Karré aus

Was uns ausmacht? Dass es bei uns persönlich zugeht zum Beispiel. Dass wir im Herzen ein Familienbetrieb geblieben sind, obwohl wir mit großen Unternehmen konkurrieren. Dass wir einen eigenen Fuhrpark betreiben. Dass wir auf maximale Flexibilität setzen… Und so vieles mehr:

Wir sind Karré

Zu Hause in München

Von der bayerischen Landeshauptstadt aus steuern wir alle Projekte.

Partner in Ungarn

Zeitintensive Handarbeiten fertigen über 100 Mitarbeiter in unserem ungarischen Werk.

Erfahrung seit 1977

Viel Erfahrung, noch mehr Wissen: Wir sind EMS-Dienstleister seit über 45 Jahren.

Ihr Plus mit uns

Erfahrung

Gibt es bei uns gleich in doppeltem Sinne:

1. Unsere Mitarbeiter

Wir setzen auf Kontinuität. Unsere Mitarbeiter haben in der Regel jahrelange Erfahrung in ihren jeweiligen Tätigkeiten.

2. Unsere Firmengeschichte

Wir produzieren Leiterplatten seit 1977 – inzwischen in zweiter Generation.

Flexibilität

Wir wissen, dass sich Pläne manchmal ändern können – und sind bestens darauf vorbereitet:

- Mindset: Wir finden eine Lösung

- Rohstoffe: Mit unserem globalen Netzwerk vermeiden wir Abhängigkeiten

- Produktion: Wir fertigen ausschließlich in Europa

- Lieferzeiten: Ein eigener Fuhrpark macht uns unabhängig und extrem schnell

Nachhaltigkeit

Wir schützen unsere Mitarbeiter und die Umwelt aktiv. Konkret heißt das:

- Heizbetrieb mit nachwachsenden Rohstoffen am ungarischen Standort

- Keine Leerfahrten unserer Lkw durch gezieltes Materialmanagement

- Wiederverwendung von Verpackungsmaterialien

- Ausdrückliche Verurteilung der Menschenrechtsverletzungen und Umweltzerstörung in der Kongo-Region mit Blick auf „Conflict Materials“ wie Gold, Tantal, Wolfram und Zinn.

Zuverlässigkeit

Wir wissen um die Bedeutung absoluter Zuverlässigkeit auf allen Ebenen. Für uns bedeutet das:

- Termine einzuhalten

- Auf langjährig erprobte Lieferanten zu setzen

- Standards, Normen und Zertifizierungen zu erfüllen

- Für unsere Kunden (fast) jederzeit persönlich erreichbar zu sein

Sicherheit

Ob RoHS, DSGVO oder die Versorgungssicherheit von Bauteilen: Wir setzen auf maximale Sicherheit.

- RoHS: Unsere Materialien entsprechen den Richtlinien.

- DSGVO: Wir gewährleisten maximale Traceability im Einklang mit der DSGVO

- Versorgungssicherheit: Wir beschaffen Bauteile und Rohstoffe vorausschauend – Platz ist in unserem eigenen Lager genug.

Qualität

Wir produzieren mit höchster Präzision. Dafür setzen wir kompromisslos auf:

- bestens ausgebildete Mitarbeiter, die in der Regel über viele Jahre bei uns beschäftigt sind.

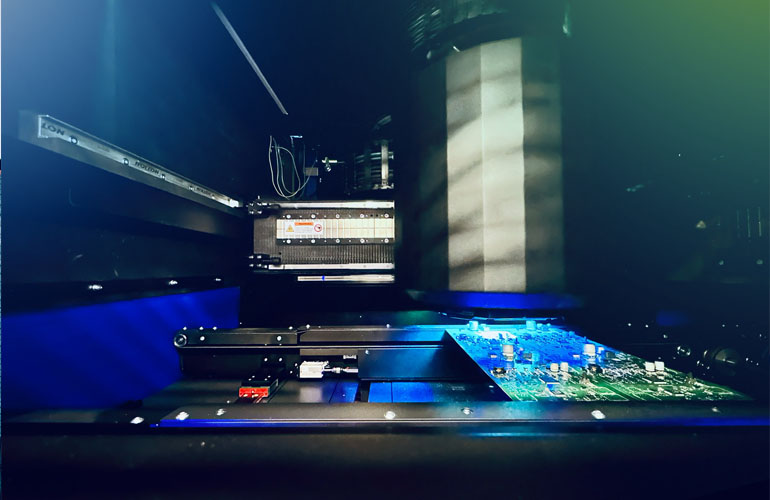

- einen modernen Maschinenpark und aktuelle Software

- die Karré-DNA, die uns antreibt, Prozesse kontinuierlich zu hinterfragen und optimieren.

Weil Qualität für uns das A und O ist, halten wir selbstverständlich an alle gängigen Normen und Standards.

Unsere Standorte

Schnell, flexibel, präzise und zugleich preisbewusst: Dank unserer beiden europäischen Standorte vereinen wir teils gegensätzlich scheinende Maxime. Und das geht so:

München

Der Karré-Stammsitz. Von der bayerischen Landeshauptstadt betreuen wir unsere Kunden und steuern sämtliche Projekte.

Auch die automatisierten Prozesse der SMD-Fertigung und die Endkontrolle sind hier zu Hause.

Dévaványa (Ungarn)

Die langjährigen Mitarbeiter an unserem ungarischen Standort Dévaványa übernehmen vor allem zeitintensive und komplexe Handarbeiten. Das macht uns insbesondere für Partner interessant, die zwar an den Kosten sparen wollen, nicht aber an der Qualität.

Unser firmeneigener Fuhrpark bringt die fertig produzierten Aufträge dann flexibel und schnell ans Ziel.

Bauteilschutz, Qualität und Umwelt: Unsere Zertifikate und Normen

Wir wollen Transparenz, die Vertrauen schafft. Deshalb lassen wir uns bereits seit 2002 regelmäßig von unabhängigen Prüfern und Kunden aus den Bereichen Industrie, Automotive, Medizin und Energietechnik zertifizieren und halten uns freiwillig an zahlreiche internationale Normen. Im Fokus: Sicherheit und Qualität.

Bauteil- und Komponentenschutz

EN 61340-5-1 & J-ESD-625 & IPC/ESD S.20.20 & ANSI/ESD S20.20

Wir schützen elektronische Bauelemente, Baugruppen und Geräte kontrolliert gegen elektrostatische Phänomene.

IPC J-STD-033

Wir richten uns nach den internationalen Standards für Handhabung, Verpackung, Versand und Einsatz von feuchtigkeitsempfindlichen Bauelemente.

IPC J-STD-020

Wir klassifizieren feuchtigkeitsempfindliche Bauteile, trocknen und verarbeiten diese entsprechend der Norm, damit diese während des Lötvorgangs nicht vorgeschädigt oder zerstört werden.

EN ISO 9001:2015

Weil Qualität für uns das A und O ist, richten und zertifizieren wir uns bereits seit 2002 ganz offiziell nach dem Qualitätsmanagement der ISO 9001.

Zum Zertifikat

IPC-A-610 & IPC-7711B/-7721

Wir beachten die weltweit am häufigsten angewendete Richtlinie für die Montage von Elektronik. Wir fertigen, überarbeiten und nehmen alle elektrischen Baugruppen nach IPC IPC-A-610 und IPC-7711B/-7721 ab. Unsere Mitarbeiter sind entsprechend geschult und zertifiziert.

IPC J-STD-001

Wir erfüllen die Anforderung an gelötete elektrische und elektronische Baugruppen.

DIN EN ISO / IEC80079-34

Unser Qualitätsmanagement beachtet bei der Herstellung von Produkten in explosionsgefährdeten Bereichen die Standards dieser Normen.

Qualität

Weitere Standards

Nachhaltigkeit: EN ISO 14001

Seit 2020 richten und zertifizieren wir uns nach dem weltweiten Standard für betriebliches Umweltmanagement.

Zum Zertifikat

Verhaltenskodex

Wir haben uns zu einer gesellschaftlichen und verantwortlichen Unternehmensführung verpflichtet. Dazu zählen für Karré insbesondere Arbeitsbedingungen, Sozial- und Umweltverträglichkeit, Wettbewerb und Transparenz über unser ethisch und rechtlich einwandfreies Handeln.