Elektronikfertigung aus einer Hand

Mit der Erfahrung aus vier Jahrzehnten Elektronikfertigung übernehmen wir die gesamte Produktion Ihrer elektronischen Baugruppen – und das von der Bestückung bis zu Techniken wie dem Vergießen oder der Lackierung. Liefern Sie unserem Team in München einfach Ihre Daten, um alles Weitere kümmern wir uns.

Ihre Vorteile auf einen Blick

Erfahren

Wir produzieren Baugruppen bereits seit 1977.

Schnell

Für Ihre Elektronikherstellung schalten wir den Turbomodus ein.

Flexibel

Ein Bauteil ist nicht lieferbar? Wir finden Ersatz.

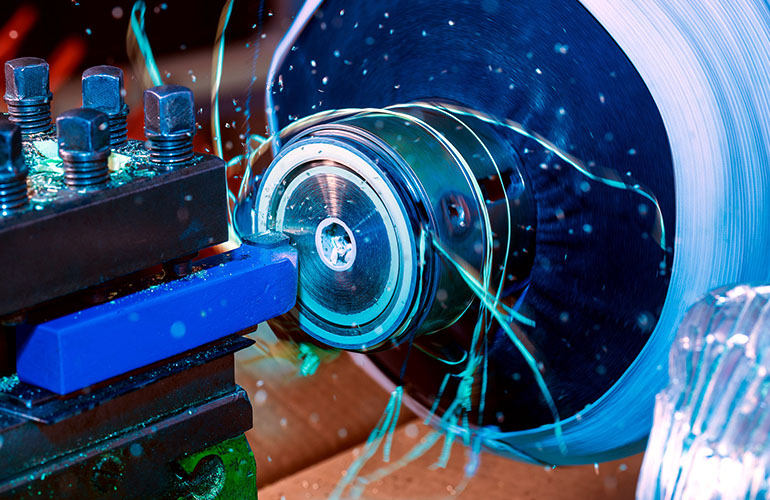

Unsere Techniken für Ihre Elektronikfertigung

Bestückung und Montage

SMT, THT, Press-Fit: Wir bieten Ihnen alle gängigen Fertigungsverfahren für die Baugruppenfertigung und Leiterplattenbestückung – und das für die Prototypen-Produktion genauso wie für Großserien. Global Sourcing, eigene Logistik und Traceability sind inklusive – auf Wunsch sogar bis auf Bauteilteilebene.

Elektronikfertigung Next Level: Alle Ihre Möglichkeiten auf einen Blick

Für Ihr EMS-Projekt bieten wir Ihnen alle Optionen. Sie können uns mit der kompletten Produktion beauftragen oder aus einzelnen Zusatzleistungen wählen. Der Überblick:

Wer wir sind: Über Karré

Bei Karré verstehen wir uns als klassisches EMS-Unternehmen in Familientradition, das aus der Erfahrung seiner Gründergeneration schöpft und jetzt in zweiter Generation noch moderner auftritt.

Rund 50 Mitarbeiter bilden das Rückgrat unserer Firma in München, 120 weitere unterstützen die Produktion in Ungarn. An beiden Standorten steht Karré für persönlichen Kontakt, höchste Qualität und flexibelste Umsetzung.