Supply-Chain-Management: Punktlandung für Ihre EMS-Projekte

Vom Rohstoff bis zu Ihrer fertigen Baugruppe: Wir planen und steuern den Prozess Ihrer Platinenproduktion über die gesamte Wertschöpfungs- und Lieferkette – auf Wunsch inklusive Obsoleszenz-Überwachung und Einhaltung der Material Compliance.

Dafür setzen wir auf etablierte Supply-Chain-Programme wie Kanban-Steuerung und Just-in-Time-Lieferungen. So stellen wir sicher, dass Rohstoffe, Komponenten und Lieferanten maximal performant aufeinander abgestimmt sind.

Ihre Vorteile auf einen Blick

Strategischer Einkauf

Wir kaufen Ihre Bauteile weltweit ein und finden sogar schwer beschaffbare Teile. Bei Lieferengpässen recherchieren wir für Sie gleichwertige Alternativen. Unser Fokus: Kosten- und/oder lieferzeitoptimierte Stücklisten ganz nach Ihrem Bedarf.

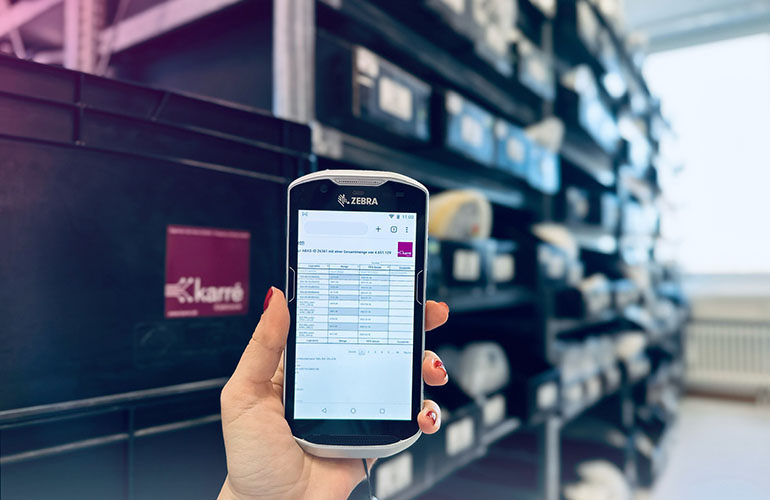

Professionelle Lagerhaltung

Nahtlos, störungsfrei und flexibel, so soll jedes Ihrer Projekte bei uns ablaufen. Deshalb verwalten wir Ihre Komponenten basierend auf deren Produktionsdatum und gleichen Mindestbestände und Liefertermine mit Ihren Wünschen ab. Individuell und nach Maß.

Großes Lieferanten-Netzwerk

Wir sind bestens mit regionalen und globalen Lieferanten vernetzt. Wunsch-Bauteile oder gleichwertige Alternativen beschaffen wir dadurch in Windeseile. Bei Bedarf spüren wir selbst Restbestände abgekündigter Bauteile auf, kaufen sie für Sie auf Vorrat ein und lagern sie bei uns.

Präzises Supply-Chain-Management

Um Sie zuverlässig beliefern zu können, achten wir bereits zu Produktionsbeginn auf langfristig verfügbare Bauteile.

Dafür beobachten wir kontinuierlich den Weltmarkt und arbeiten mit verschiedenen Lieferanten zusammen.

So können wir eine eventuelle Allokation von Elektronik-Bauteilen und Komponenten früh einschätzen und von Vornherein umgehen. Mit SiliconExpert bekommen wir dafür Unterstützung von einem der weltweit führenden Tools im Supply-Chain-Management.

Kanban Materialmanagement und Just-in-Time-Lieferung.

Sie wollen immer einen Mindestbestand an Materialien auf Lager haben, gleichzeitig aber in Ihrem Unternehmen keine Kräfte fürs Materialmangement binden? Dann lagern Sie das doch einfach an uns aus! Dank Kanban-Steuerung beliefern wir Sie selbständig und sorgen dafür, dass Sie jederzeit produktionsfähig sind.

Keine Nerven, kein Platz oder kein Personal für ein eigenes Lager? Mit dem Just-in-Time-Management von Karré sind Ihre Materialien immer zum passenden Zeitpunkt mit der passenden Menge am richtigen Ort.

Obsoleszenz-Management

Vorsorge ist besser als Nachsorge: Damit Sie Ihr Produkt zuverlässig über Jahre hinweg produzieren können, können Sie mit uns optional auf ein effektives Obsoleszenz-Management Ihrer Elektronik-Bauteile setzen.

Damit berücksichtigen wir schon bei der Planung die langfristige Verfügbarkeit der einzelnen Komponenten. Wir überwachen proaktiv den Weltmarkt und können schnell mit einer last-timy-buy-order reagieren, sollten kritische Bauteile abgekündigt werden.

Auf Wunsch lagern wir die aufgekauften Restbestände auch mehrere Jahre bei uns ein.

Material Compliance: Wir setzen auf höchste Qualitätsstandards

Wir sind uns unserer Verantwortung bewusst und arbeiten mit RoHS-konformen Materialien sowie gemäß der europäischen REACH-Verordnung.

Auf Wunsch prüfen wir Ihre Stücklisten auf die Material Compliance, beraten Sie zu den laut RoHS-Richtlinien zugelassenen Höchstwerten insbesondere bei Elektronik-Bauteilen und suchen gegebenenfalls geeignete Alternativen für Sie.

Conflict Minerals: Für eine saubere Umwelt

Unter “Conflict Minerals”, wie sie unter den Vorgaben des Dodd-Frank Act beschrieben werden, fallen Gold, Tantal, Zinn und Wolfram (3TG), sowie zusätzlich Kobalt und Mica. Diese Reinstoffe werden oft als unvermeidlicher Bestandteil in elektronischen Komponenten und Produkten eingesetzt.

Karré Elektronik ist sich der Tragweite der „Conflict Minerals“ Problematik bewusst und unterstützt unter den Aspekten der Nachhaltigkeit und globalen sozialen Verantwortung die Initiative für eine konfliktfreie Versorgung der Industrie mit oben genannten Reinstoffen (3TG). Deshalb befürworten wir die Unterbindung eklatanter Menschenrechtsverletzungen und massiver Umweltzerstörung in der Demokratischen Republik Kongo und benachbarter Länder und Regionen.

Als Dienstleister und Auftragsfertiger innerhalb der Elektronikindustrie haben wir selbst nur einen geringen Einfluss auf die Produktion und Verwendung dieser Materialien in elektronischen Komponenten. Wir erwarten daher von unseren Lieferanten und deren Unterlieferanten nur 3TG, Kobalt und Mica von aktiven und konformen Einrichtungen (RMI-Liste aktiver und konformer Einrichtungen (responsiblemineralsinitiative.org) zu verarbeiten.

Ferner fordern wir unsere Lieferanten auf, sich auf der Website des RMI über aktuelle Änderungen zu informieren (Initiative für verantwortungsvolle Mineralien (responsiblemineralsinitiative.org) und für die Berichtserstattung die aktuelle Vorlage für die Meldung von Konfliktmineralien (responsiblemineralsinitiative.org) sowie die Erweiterte Berichtsvorlage für Mineralien (responsiblemineralsinitiative.org) zu verwenden.

Karré Elektronik selbst wird weder absichtlich noch wissentlich Produkte verwenden, die Konflikt-Mineralien aus diesen Regionen enthalten.

Wer wir sind: Über Karré

Bei Karré verstehen wir uns als klassisches EMS-Unternehmen in Familientradition, das aus der Erfahrung seiner Gründergeneration schöpft und jetzt in zweiter Generation noch moderner auftritt.

Rund 50 Mitarbeiter bilden das Rückgrat unserer Firma in München, 120 weitere unterstützen die Produktion in Ungarn. An beiden Standorten steht Karré für persönlichen Kontakt, höchste Qualität und flexibelste Umsetzung.