Platinen und Baugruppen prüfen lassen: Für höchste Leiterplatten-Qualität

Auf Wunsch mehrfach geprüft von Mensch und Maschine: Das ist unser Versprechen an Sie. Neben der automatischen optischen Inspektion (AOI) prüfen wir Ihre Leiterplatten optional mittels einer elektrischen Funktionskontrolle sowie eines In-Circuit-Tests (ICT).

Darüber hinaus können wir insbesondere bei sicherheitsrelevanten Elektronik-Schaltungen, elektronischen Geräten und Baugruppen Hochspannungsprüfungen in den verschiedenen Fertigungsstadien durchführen.

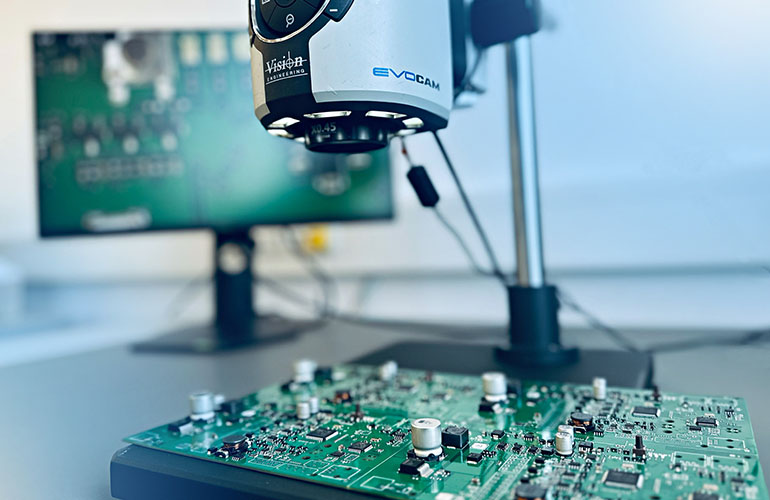

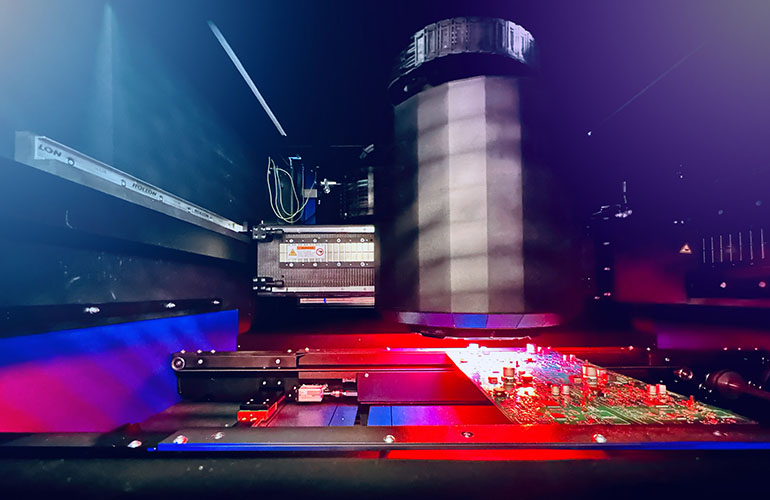

Automatische optische Inspektion (AOI)

Die automatische optische Inspektion AOI ermöglicht uns, Ihre Platinen mit höchster Präzision zu prüfen. Mit Hilfe von RGBW-Licht können wir beispielsweise die Qualität der Lötstellen prüfen. Darüber hinaus erkennen unsere 3D-AOI-Anlagen etwa geringste Abweichungen vom erwarteten Höhenprofil der Bauteile. Das lässt Rückschlüsse darauf zu, ob ein Bauteil bei der Bestückung zum Beispiel verkippt sein könnte.

Ihr Vorteil: Mit der AOI lassen sich verlässlich sämtliche Farb-, Positions- und Lötfehler identifizieren und korrigieren, welche beim Bestücken und nachfolgendem Reflowlöten, Selektivlöten, Handlöten oder Wellenlöten auftreten können. Das Ergebnis: Einwandfreie Platinen.

Die AOI ist einer der wirksamsten und wichtigsten Schritte unserer Leiterplatteninspektion. Damit sortieren wir fehlerhafte Platinen automatisch aus, lassen sie von geschulten Mitarbeitern nacharbeiten und erneut prüfen. So vermeiden wir effektiv, dass fehlende, verdrehte, versetzte oder falsch bestückte Bauteile später zu vermeidbaren Fehlern führen. Noch vor dem nächsten Bearbeitungsschritt identifizieren und korrigieren wir daher solche Fehler.

Vorteile der AOI auf einen Blick

Digitale Bildverarbeitung

Wir erfassen jede produzierte Einheit mittels Bildverarbeitung digital und vergleichen sie mit einer einwandfreien Referenzbaugruppe. So prüfen wir Ihre Platinen ganz genau und entdecken sofort etwaige Produktionsfehler.

Gezielte Reparatur

Wir setzen auf Handarbeit: Unser geschulten Mitarbeiter bessern die als fehlerhaft identifizierte Leiterplatten manuell aus, bevor sie erneut geprüft werden. Das Ergebnis: Einwandfreie Baugruppen.

Digitale Traceability

Wir erfassen per Scan die einzelnen Durchläufe und zeichnen die Bilder der Baugruppe unter der jeweiligen Baugruppen-ID auf. Sämtliche Produktionsschritte sind somit für Sie auf Wunsch lückenlos nachverfolgbar.

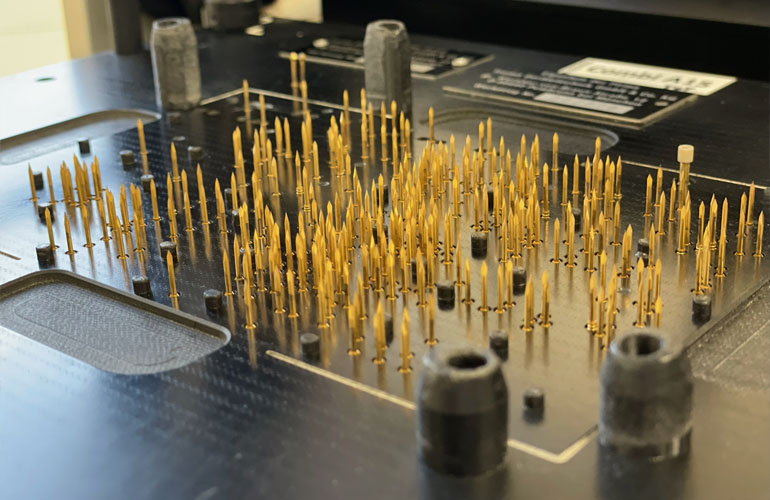

Elektrische Funktionskontrolle (FCT) und In-Circuit-Test (ICT)

Doppelt hält besser: Neben der AOI prüfen wir Leiterplatten mittels elektrischer Funktionskontrolle sowie dem In-Circuit-Test (ICT). Dadurch sichern wir sowohl THT- als auch SMD-Bauformen nahezu vollumfänglich ab und garantieren eine gründliche Inspektion Ihrer Platinen.

Lassen Sie die Ein- und Ausgangssignale kompletter Baugruppen messen! Beim Funktionstest stellen wir sicher, dass Ihre THT- und SMD-Platinen einwandfrei arbeiten. Die Testergebnisse liefern wir Ihnen auf Wunsch mit. So können Sie auch noch nach Jahren Feldausfälle analysieren, vergleichen und Ihre Prüfabläufe optimieren.

In-Circuit-Test lässt sich für die verschiedensten THT- und SMD-Bauformen umsetzen. Dabei messen wir über ein Nadelbett die Ein- und Ausgangssignale einzelner Komponenten.

Vorteile von FCT und ICT auf einen Blick

Vergleichsmessung

Bei Bedarf simulieren wir die Eingangssignale einer Baugruppe und vergleichen die Ausgangswerte mit den Spezifikationen. Die Parameter und Messwerte erfassen wir in einer Datenbank, archivieren und liefern sie auf Wunsch an Sie mit.

Weiterentwicklung

Dank der erfassten Daten können Sie Feldausfälle auch nach Jahren analysieren und mit den früheren Testergebnissen vergleichen. So können Sie nachfolgende Versionen stets verbessern. Natürlich stehen wir Ihnen dabei beratend zur Seite.

Traceability

Ihre Baugruppe kommt in kritischen Bereichen zum Einsatz? Gerne erfassen wir alle verbauten Komponenten, Fertigungs- und Prüfschritte Ihres Produktes. Unsere Garantie: Eine lückenlose Rückverfolgbarkeit von mindestens zehn Jahren über die gesamte Wertschöpfungskette.

Burn-in-Tests zur beschleunigten Voralterung

Ihre Bauteile sind hohen Belastungen ausgesetzt und müssen besonders beständig sein? Kein Problem, auf Wunsch führen wir Burn-In-Tests für die beschleunigte Voralterung durch. Einzelkomponenten einer Baugruppe können so auf ihre Anfälligkeit hin geprüft werden – so wird die Tauglichkeit für die spezifizierten Anwendungsbereiche gewährleistet.

Wer wir sind: Über Karré

Bei Karré verstehen wir uns als klassisches EMS-Unternehmen in Familientradition, das aus der Erfahrung seiner Gründergeneration schöpft und jetzt in zweiter Generation noch moderner auftritt.

Rund 50 Mitarbeiter bilden das Rückgrat unserer Firma in München, 120 weitere unterstützen die Produktion in Ungarn. An beiden Standorten steht Karré für persönlichen Kontakt, höchste Qualität und flexibelste Umsetzung.