Bestückung und Montage von Leiterplatten

Präzise, schnell, flexibel und von garantiert verlässlicher Qualität: So stellen Sie sich die Bestückung Ihrer Platinen vor? Wir auch. Die manuelle und automatisierte Leiterplattenbestückung mit THT und SMD Bauteilen zählt zu unseren Kernkompetenzen – auf Wunsch inklusive der anschließenden Baugruppenmontage.

Welche Lösung für Ihr Unternehmen ideal ist, klären wir in einem persönlichen Gespräch. Auch das zählt zur DNA von Karré als Münchner Familienunternehmen: Die persönliche Nähe zu unseren Kunden.

Ihre Vorteile auf einen Blick

Schnelligkeit

Vom Prototypen bis zur Kleinserie: Sie halten Ihre fertige Baugruppe maximal schnell in den Händen. Im Extremfall schaffen wir das binnen weniger Stunden im Raum München.

Full Service

Alle Dienstleistungen für Ihre Baugruppen aus einer Hand: Wir kümmern uns um jeden Schritt vom Material-Einkauf über die Bestückung, Prüfung, Lackierung und Leiterplattenmontage bis hin zu Verguss und Verpackung.

Traceability

Ihre Baugruppe kommt in kritischen Bereichen zum Einsatz? Wir erfassen alle verbauten Komponenten, Fertigungs- und Prüfschritte zur lückenlosen Nachverfolgung.

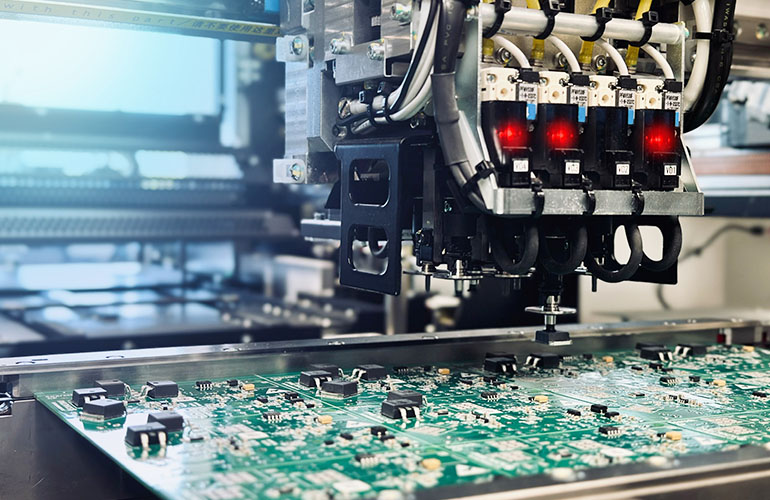

Hochmoderne Anlagen

Ihre Produkte werden bei Karré in Maschinen bearbeitet, die höchste Geschwindigkeit, Präzision und Reproduzierbarkeit garantieren.

Global Sourcing

Aus der Welt nach München: Wir kaufen unsere Rohstoffe und Komponenten global ein. Strategisch, zuverlässig, auch bei schwer beschaffbaren Bauteilen.

Flexibilität

Schnell und unkompliziert die eigenen Prototypen bestücken lassen? Doch mehr Baugruppen benötigt als gedacht? Dank flacher Hierarchien sind wir extrem flexibel und ermöglichen fast alles.

Eigene Logistik

Mit unserer eigenen Lkw-Flotte und unseren Fahrern sind wir unabhängig von den Launen des Logistikmarktes. Das macht uns schneller und effizienter als viele Mitbewerber.

Menschlichkeit

Wir sind ein Familienunternehmen. Das spiegelt sich auch im Umgang mit unseren Mitarbeitern wider. Vielleicht ist das der Grund, aus dem uns die meisten seit Jahren treu bleiben.

Qualität

Qualität ist für uns mehr als ein Schlagwort: Wir setzen auf bestens ausgebildete Mitarbeiter, sorgfältig ausgewählte Lieferanten und strenge Qualitätskontrollen.

Wir produzieren für KMUs genauso wie für Konzerne

Zu unseren Stammkunden gehören Unternehmen jeglicher Größe: StartUps, mittelständische Unternehmen und Global Player. Ihre Vorteile auf einen Blick:

- Starker Standort mit 50 Mitarbeitern in München

- Wir produzieren Ihre Kleinserien ebenso wie Prototypen für global Player und Dax-Unternehmen

- Wenn Sie eine Frage haben, dann klären wir diese unmittelbar – gerne auf dem kurzen Dienstweg.

- Karré ist ein Familienunternehmen in zweiter Generation: Aus Passion gegründet, erfolgreich gewachsen, verantwortungsbewusst seinen Mitarbeitern und Kunden gegenüber.

Vom Prototypen bis zur Großserie

So vielfältig wie unsere Kunden sind auch die Möglichkeiten unserer Produktion. Platinenbestückung können wir vom Einzelstück bis zum millionenfachen Auftrag umsetzen.

- Kleinstmengen wie Prototypen ab 1 Stück

- Musterserien bis zu 50 Stück

- Kleinserien bis zu 1.000 Stück

- Großserien bis zur millionenfachen Bestückung

SMT, THT und Press-Fit: Welche Bestückung soll es sein?

Manuelle oder maschinelle Bestückung von Platinen: Das ist eine der Grundfragen bei der Entscheidung für SMT (Surface-mount technology) oder THT (Through-hole technology). Bei Karré setzen wir auf beide Verfahren.

Maschinelle SMD-Bestückung

Höchst präzise, unschlagbar schnell und vor Ort bei uns in München: Unser SMD-Maschinenpark ist das Herzstück unserer Leiterplattenbestückung.

• Möglichkeiten von der kleinsten Bauform 0201 metrisch bis maximal 120x90x40mm oder 150x25x40mm

• Bestückgenauigkeit von ±25µm bei Cpk ≥1

• Linien-Geschwindigkeit bis zu 106.000 Bauteile pro Stunde

• Einstellbare Bestückkraft bis 100N

• Maximale Platinengröße 780x610mm

Manuelle THT-Bestückung

Wir setzen auch weiterhin auf den Faktor Mensch! Bestens ausgebildete und hoch motivierte Mitarbeiter übernehmen bei uns die manuelle Bestückung von Leiterplatten.

• Flexible Produktionskapazitäten

• Freie Wahl der Bauteilgröße

• Wellenlöten unter Stickstoffatmosphäre für höchste Lötqualität

• Traditionelle und konkurrenzfähige Handarbeit am Standort Ungarn

• Schneller Transport von Bauteilen und fertigen Baugruppen durch firmeneigene Lkw-Flotte

So garantieren wir höchste Qualität

Zu unserer Definition von gleichbleibend hoher Qualität zählt auch die systematische Bauteil- und Baugruppenprüfung mit unseren Standard-Testverfahren AOI, ICT, Funktionstest. Wie bei jedem Produktionsschritt setzen wir auch hier auf bestens ausgebildete Mitarbeiter.

10 Jahre Traceability: Das Plus für Ihr Risikomanagement

Bei Bedarf erfassen wir lückenlos alle verbauten Komponenten, Fertigungs- und Prüfschritte Ihrer Platinen. Unsere Traceability umfasst den gesamten Bestückungsprozess von der Warenannahme über die Lieferscheindaten der Einzelkomponenten bis hin zur Fertigstellung und Übergabe. Unsere Garantie: eine lückenlose Rückverfolgbarkeit von mindestens zehn Jahren für jedes noch so kleine Bauteil über die gesamte Wertschöpfungskette.

Wer wir sind: Über Karré

Bei Karré verstehen wir uns als klassisches EMS-Unternehmen in Familientradition, das aus der Erfahrung seiner Gründergeneration schöpft und jetzt in zweiter Generation noch moderner auftritt.

Rund 50 Mitarbeiter bilden das Rückgrat unserer Firma in München, 120 weitere unterstützen die Produktion in Ungarn. An beiden Standorten steht Karré für persönlichen Kontakt, höchste Qualität und flexibelste Umsetzung.