Unterstützung für die Produktentwicklung Ihrer Platinen und Baugruppen

Wir kennen Ihre Herausforderungen bei der Entwicklung von Leiterplatten und Baugruppen und unterstützen Sie bei allen aufkommenden Fragen wie:

- Ist die Fertigungsliste vollständig?

- Entspricht das Platinenlayout den Normen und gesetzlichen Vorgaben?

- Lässt sich die Leiterplatte überhaupt so fertigen wie geplant?

- Welche Folgetechnologien könnten abgekündigte Bauteile ersetzen?

- Wer hilft uns bei VDE-, UL- und ATEX-Zulassungen?

- Und gibt es vielleicht ganz neue, alternative Lösungsansätze?

Leiterplatten entwickeln lassen: Ihre Vorteile mit Karré

DFM-Analyse

Sie bekommen Feedback aus Produktionssicht zu Ihren firmeneigenen Platinen-Entwicklungen.

Konformitäts-Check

Ob REACH, gesetzliche Normen oder andere Regelungen: Wir klären, ob alles passt.

Initiativ-Entwicklung

Wir kommen initiativ auf unsere Kunden zu, wenn wir von modernen Lösungen erfahren.

Unabhängige Testhäuser

Unsere Partner unterstützen Sie bei allen Zulassungen von VDE über UL bis ATEX.

Neuentwicklungen

Einfache Anwendungen entwickeln wir auf Wunsch komplett neu für Sie.

Obsoleszenz Management

Wir finden Alternativen für Folgetechnologien und nach Bauteil-Abkündigungen.

EMS-Development: Dem Wettbewerb einen Schritt voraus

Zapfen Sie unser Wissen an!

Qualität ist das, was uns bei Karré antreibt – und das schon vor der Produktion Ihrer Leiterplatten. Wir bekommen Änderungen am Markt schnell mit. Neue Technologien, neue Normen, neue Bauteile: Unser Wissen geben wir gerne an Sie weiter.

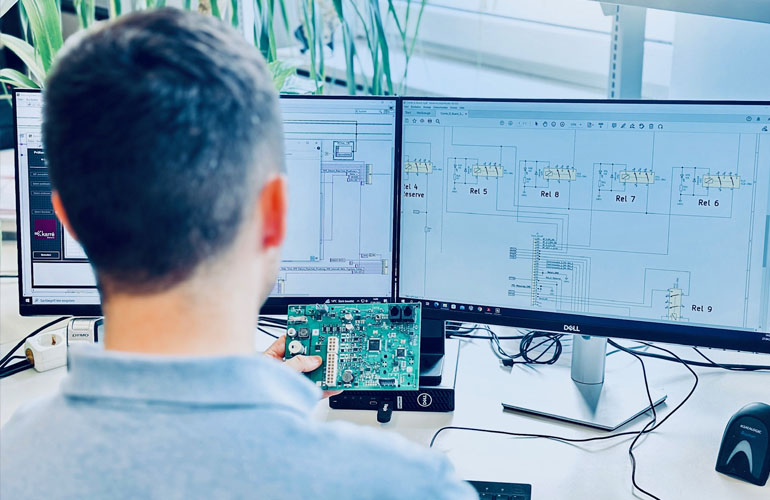

Holen Sie sich einen erfahrenen Sparringspartner bei der Entwicklung

Die Karré-eigene Entwicklungsabteilung steht Ihnen in jeder Projektphase mit fundiertem Rat und versierter Tat zur Seite. Wir unterstützen Sie beispielsweise bei:

- Der Entwicklung der für Ihr Projekt individuell passenden Prüfstrategie.

- Der Entscheidung für die am besten geeigneten und verfügbaren Komponenten und Bauteile.

- Der Erstellung von Schaltplänen und Platinenlayouts.

Setzen Sie aufs Schwarmwissen: Wir bringen alle Experten an einen Tisch

Gemeinsam kommen wir ans Ziel. Deshalb setzen wir auf Lösungen aus einer Hand.

Bei komplexen Aufgabenstellungen bringen wir Spezialisten aus allen Bereichen zusammen.

- Kunststofffertigung

- Automatisierung

- Verbindungstechnik

- Feinmechanik

- Druckguss

- Leiterplattenlayout und -fertigung

- Prüfung und Logistik

Wer wir sind: Über Karré

Bei Karré verstehen wir uns als klassisches EMS-Unternehmen in Familientradition, das aus der Erfahrung seiner Gründergeneration schöpft und jetzt in zweiter Generation noch moderner auftritt.

Rund 50 Mitarbeiter bilden das Rückgrat unserer Firma in München, 120 weitere unterstützen die Produktion in Ungarn. An beiden Standorten steht Karré für persönlichen Kontakt, höchste Qualität und flexibelste Umsetzung.